| |

| |

|

| |

| |

| |

||

| |

||

| |

||

|

|

|

the great Wall of China

Although the wall has suffered extended periods of neglect, parts of it have been reconstructed many times, and reconstruction continues today, usually using the same materials and techniques as the initial builders. The usual construction sequence begins with clearing and leveling the ground, placing flat stone foundation slabs on the levelled earth, and then beginning the exterior stone walls. It may appear that the design of a retaining wall is a simple process, but if you stop to consider the cost and efficiency of the design or construction, that is quite another matter. As you can see, the Great Wall uses a tremendous amount of stone An engineer designing the Great Wall today would most likely design a reinforced earth structure. In this relatively recent system, the exterior face of the wall is composed of face panels tied back into the soil behind with long, thin strips of galvanized metal or special plastic. These strips are placed in conjunction with thin (200mm-400mm) lifts, or layers, of soil that are well-compacted before the next lift is added. Although the actual mechanics of the process are much more involved, the system, very simply, works in this manner: the soil pushing against the exterior panels creates an outward thrust, or push, which is resisted by the metal or plastic strips running back into the soil. These strips are prevented from moving by the frictional resistance due to the weight of the soil sitting on them; put another way, the weight of the soil pushing down on the strips creates a greater resistance to the strip moving horizontally than does the outward thrust of the earth against the exterior panels. |

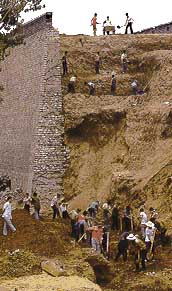

As the exterior walls progress upward, the interior space is filled with rock, earth, and rubble, and compacted in layers to minimize settlement. Exterior walls were generally constructed using bricks and mortar made from local materials and fired in kilns built at regular intervals along the length of the wall. The lower photo shows the excavation of an unusually high section of the wall, clearly delineating the exterior stone wall from the interior compacted earth fill.

As the exterior walls progress upward, the interior space is filled with rock, earth, and rubble, and compacted in layers to minimize settlement. Exterior walls were generally constructed using bricks and mortar made from local materials and fired in kilns built at regular intervals along the length of the wall. The lower photo shows the excavation of an unusually high section of the wall, clearly delineating the exterior stone wall from the interior compacted earth fill.