Three stations capable of performing drained and undrained triaxial tests give students an opportunity to explore more sophisticated soils testing. Pore pressures can be monitored and confining pressures are limited to 1MPa.

The Department of Civil Engineering maintains two geotechnical laboratories - one for "clean" testing (49 square meters floor area) and one for "dirty" testing that is shared with materials testing (391 square meters floor area). The labs are equipped to carry out a wide range of testing on soils, and we endeavor to expose students to both automated and manual methods. In the “dirty” soils lab students complete general index testing such as Atterberg Limits, sieve tests, and hydrometers, as well as permeability, proctor and unconfined compression strength testing. The lab is equipped with manual and motorized proctor hammers, manually operated soil compression machines, ovens, scales, sieve and moist rooms, and mobile permeability boards. This space is also used to prepare samples for the more advanced testing carried out in the “clean” soils lab. The clean soils laboratory provides students access to both mechanical and pneumatic consolidation machines, triaxial compression testing machines, and direct shear equipment. The consolidation and triaxial test setups are monitored by linear variable differential transformers (LVDTs) to collect accurate data over the long time periods required for consolidation. The data acquisition system also allows real time display of the data being gathered so students can evaluate the general behaviour and confirm the test is proceeding as expected. The direct shear machines can also be set up for automated readings however in most cases, students are given the opportunity to practice manual instrument reading and data recording when doing direct shear tests.

Three stations capable of performing drained and undrained triaxial tests give students an opportunity to explore more sophisticated soils testing. Pore pressures can be monitored and confining pressures are limited to 1MPa.

Four mechanical test setups allow students to clearly see how an applied load causes soil consolidation while four pneumatic test setups expose students to more modern consolidation equipment.

Four direct shear machines allow students to clearly observe the shear strength behavior of soils. Good teamwork skills are required to read the many dials that are needed for this test.

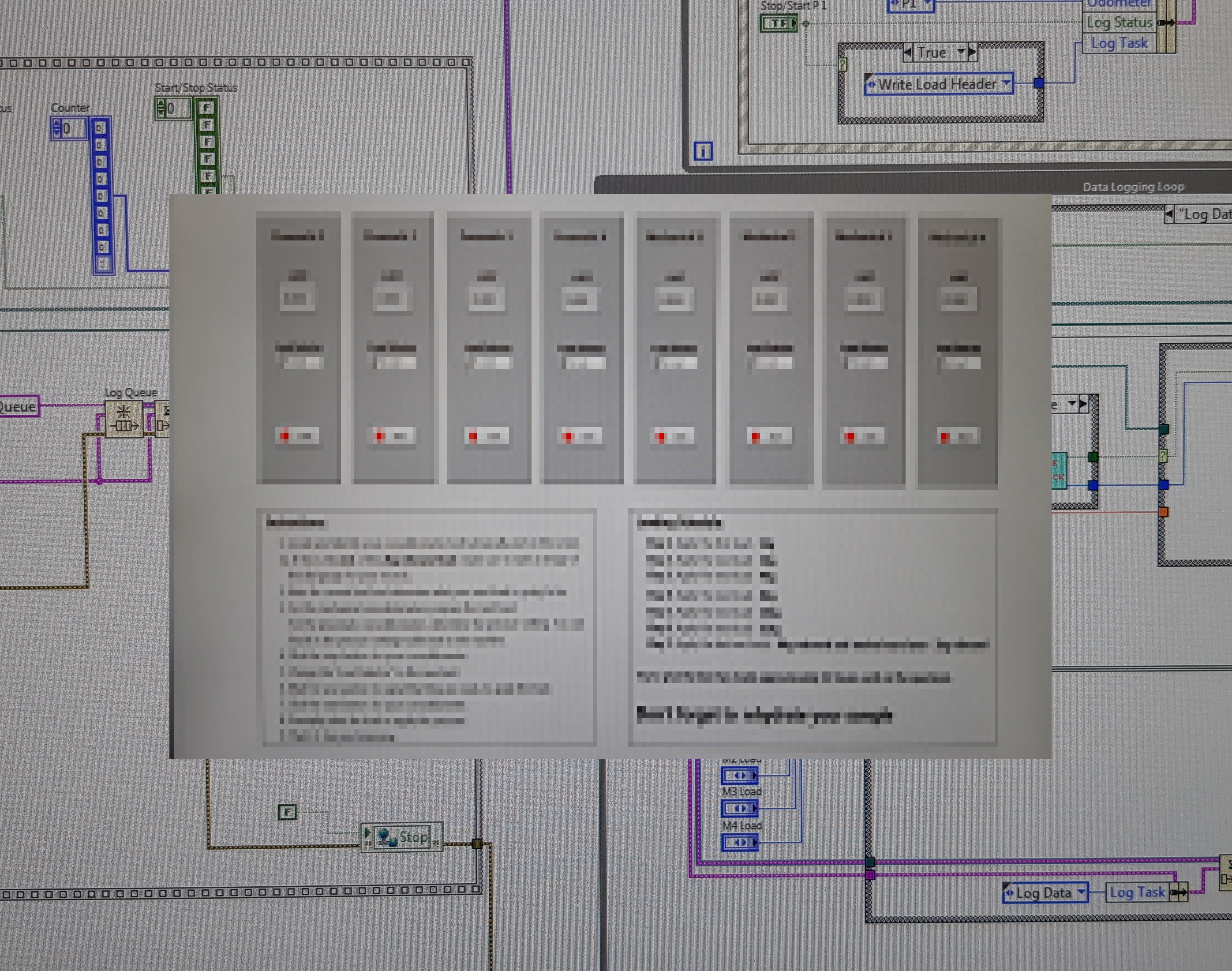

All of the test setups in the clean soils lab can be hooked up to automatic data acquisition. National Instruments DAQ software, LabVIEW, is used to collect, convert and display specimen displacement in real time.

The lab is equipped with four manual unconfined compression testing machines. Students are provided with two undisturbed specimens. Each is tested in both the undisturbed and remolded conditions.

Four portable permeability boards enable students to measure the flow of water through soil under either constant or falling head conditions.